Know Your Glove Standards - EN 407

EN 407 is the standard that provides test data for gloves that give protection from thermal hazards.

Although all thermal protection gloves come under the EN 407 category, there are six performance levels in this category depending on what level of thermal conditions you are dealing with. It’s important to find the correct Personal Protective Equipment for the task you’re carrying out, otherwise you’re likely to cause an accident or suffer injury. If you are employed full time, then your employer must supply you with the correct PPE, don’t start the job without it!

Here is what the EN 407 standard covers:

Resistance to flammability

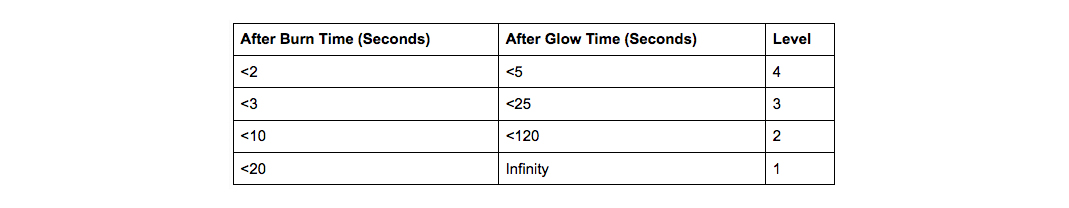

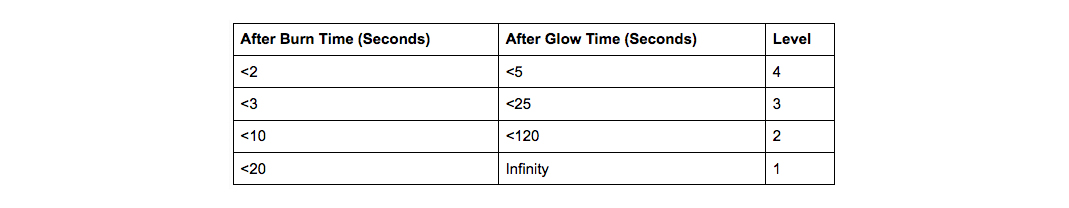

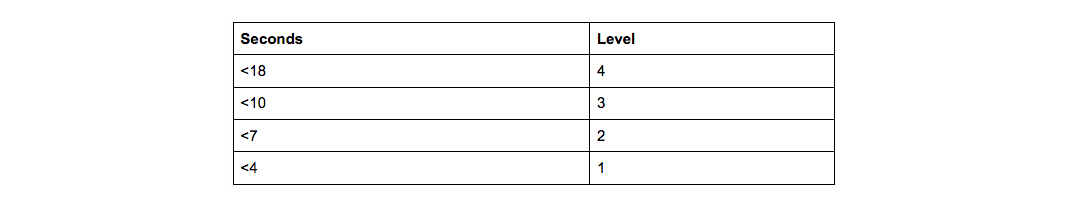

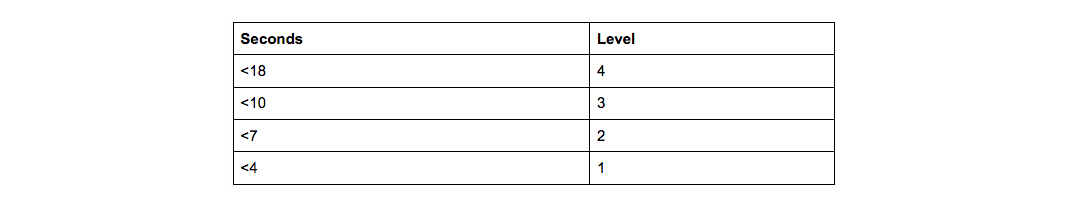

This test covers how well the gloves copes with ignition. The glove will be held in a flame for 15 seconds, and the measurements taken after are essentially how long it takes the glove to extinguish the flame and stop glowing.

The glove that extinguishes the flame and after glow in the shortest space of time will be awarded a level 4 whereas a glove that continues to burn or glow for a long period of time will be labelled with a 1. The test will also look into the seams of the glove, if they come apart after ignition then the glove will fail the test.

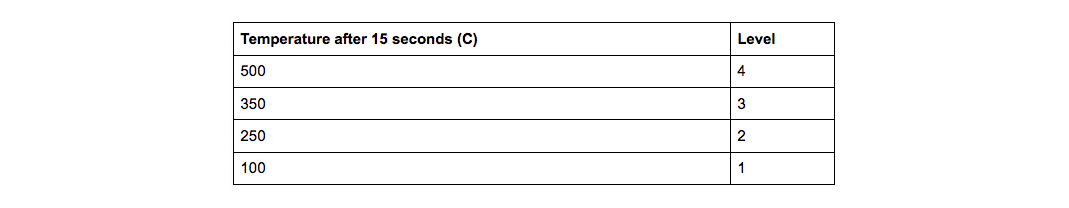

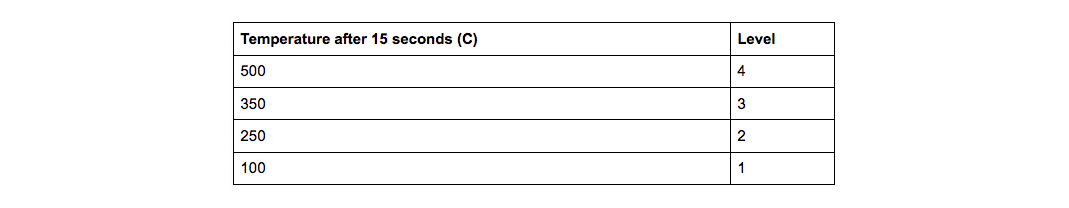

Contact heat resistance

This test looks into the interior temperature of the glove, when it is exposed to temperatures from 100°C to 500°C over a length of time of 15 seconds, to ensure that the individual wearing the gloves will not be burnt.

You will normally find that gloves at level 4 are made from Kevlar, a high quality heat resistant material and more specialist gloves sometimes feature an aluminised glass fabric cuff, to protect your wrists and arms too. Look for these extra features when purchasing your gloves, to ensure optimum protection when working with high temperatures.

Convective heat resistance

Convective heat resistance is similar to contact, except the glove is exposed to a flame rather than a contact surface. The measurements are taken from the interior of the glove, and measures how long a glove can delay the transfer of heat. Again, this is measured on a numbered scale, so consider this when making your glove purchase. This test can only be carried out on gloves which score 3 or 4 on resistance to flammability.

Radiant heat resistance

A radiant heat surface is something which gives out heat for example radiators, patio heaters, fireplaces etc. In an industrial environment however, this could be a piece of machinery that is in constant use and requires a high level of protection when employees are carrying out work with it. The test to grade radiant heat resistant in gloves measures the rising temperature of the glove’s interior, and how long an individual can go without being subjected to a risk of injury.

The 1-4 grade is an important consideration when choosing gloves for tasks working with radiant heat.

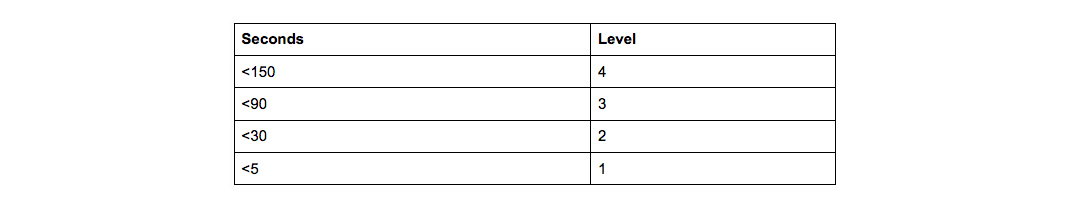

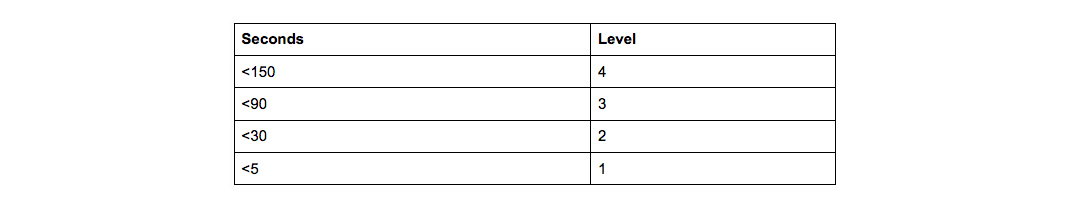

Resistance to small splashes of molten metal

Work that involves molten metal includes welding and flame cutting but you should also consider hand protection for areas where you might be at risk from a cloud of molten metal droplets or even localised impact from an explosion.

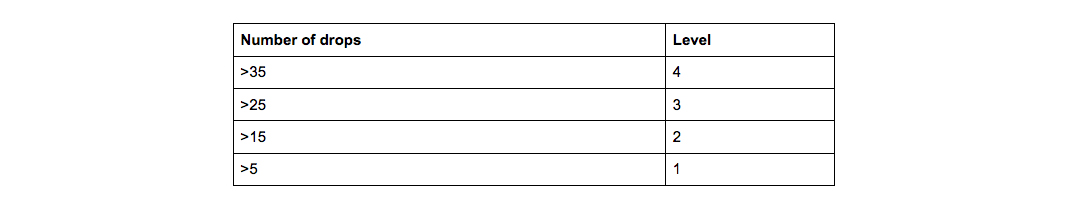

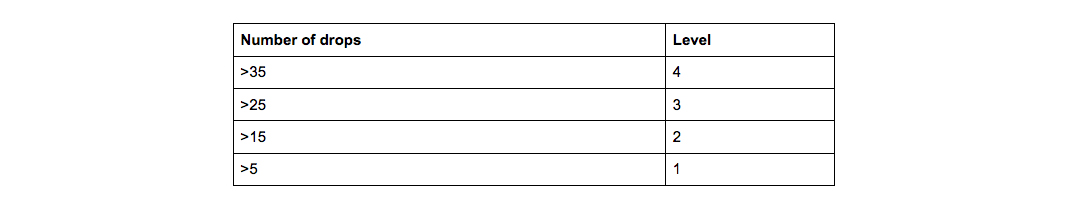

The test for gloves which are to be used in this environment involves droplets of molten metal being applied to the material, while the interior temperature is taken. The glove is measured on its ability to remain at a comfortable temperature, after the application of the molten metal drops. Here we have the grading and how resistant this means the gloves are to molten metal:

Resistance to large splashes of molten metal

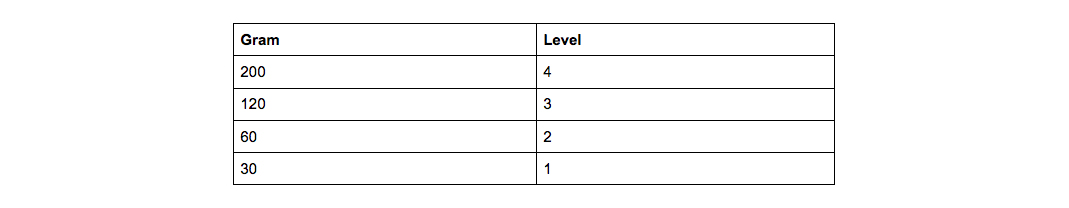

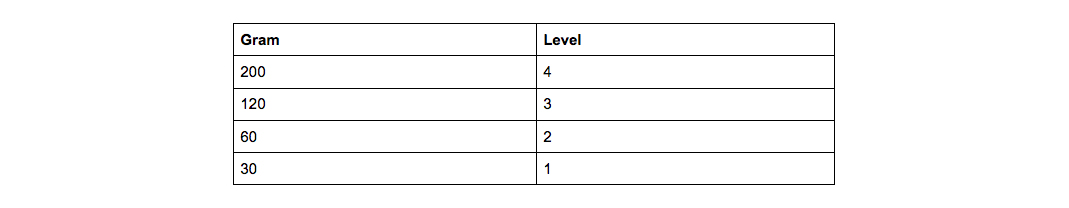

This test is similar to the small splashes of molten metal, only larger amounts of molten metal are used and the performance level is measured on the condition of the ‘simulated skin’ inserted into the glove after application and whether any pin-holing or smoothing occurs to the surface.

The stronger the glove, the more you will see the number 4 after EN407, however you may occasionally come across an X which simply means it was not tested.

Maintenance

It’s important that you follow the instructions that come with your Personal Protective Equipment, including where to store it. Most gloves require a dark and dry environment to keep them in the best condition, chances are if you leave them out in the sun for too long their effectiveness will be reduced.

Employers are also responsible to regularly check that their employees are using the correct PPE and keep replacements and supply cupboards replenished. Sometimes this means putting up safety signs to remind employees that they should be wearing the relevant equipment for the job they’re doing.