What Different Types of Disposable Gloves Are There?

When selecting the right disposable gloves for the task at hand, there is a surprising amount you need to consider. Here we have broken down each type of disposable glove avalable, plus what each one is best for and why, into an easy to follow guide:

Best for:

- mechanics

- medical professionals

- tattooists

- people with allergies to latex

- Laboratories

- Food contact

- Strength and chemical splash resistance

Why?

A popular choice for many industries, nitrile gloves are resistant to a wide variety of chemicals and other hazardous substances, as well as having good tensile properties.

Nitrile is made using synthetic rubber, making it an excellent choice for latex allergy sufferers, as it does not contain any of the same protein that could encourage a reaction.

What To Consider

Nitrile gloves should not be worn when working with electrics and it is also important to check the chemical resistance available on the gloves you purchase before working with hazardous chemicals, as permeation rates will vary depending on the actual chemical and the glove itself.

Nitrile rubber generally has a higher tensile strength and slightly greater resistance to puncture than natural rubber latex. Nitrile rubber is resistant to a range of chemicals including chemotherapy/cytotoxic drugs but again please check the resistance prior to use.

Accelerator free nitrile gloves are manufactured without the use of accelerators (carbonates, thiazides, thiurams) which reduces the risk of skin sensitivity and type IV chemical allergy.

For more information. our Complete Buyers Guide to Nitrile Gloves can help you.

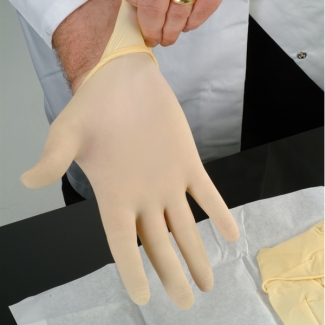

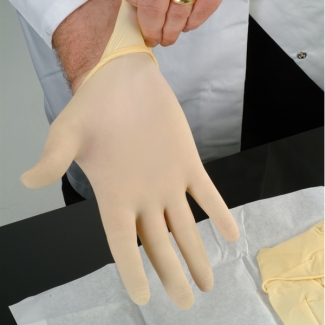

Best for:

- medical professionals

- those working in the beauty industry

- those looking for better dexterity and fit

- biodegradable features for green practices

- a glove that fits like a second skin

- those who need a high level of touch sensitivity.

Why?

Latex is said to fit like a second skin, offering touch sensitivity to ensure the task being carried is performed to a high standard so no contact is lost. These gloves offer a great deal of flexibility, meaning they’re great for tasks that require a steady hand and fluid movement.

Latex is durable and reliable when it comes to performing as a good barrier between infectious substances and to prevent cross contamination.

What To Consider

Some people suffer from allergies to latex (type I), so this is something to check for beforehand.We have a guide here that you can download here that explains latex allergy.

Latex is not resistant to many chemicals though and its puncture resistance is not as good as that offered by nitrile gloves. However, it is a biodegradable material and so if your business maintains strong green environmental practices then these gloves can be disposed of in an economic way.

For more information. our Complete Buyers Guide to Latex Gloves can help you.

Best for:

- Low risk procedures

- food preparation (except fatty food)

- hairdressers

- those looking for a looser fit

- lower budgets

- working with non-hazardous materials

- those with allergies to latex.

Why?

Vinyl gloves are completely synthetic, which means they are cheaper to make so great for low risk, shorter tasks that still require some level of protection. They are commonly used in the food industry, when preparing food to ensure the risk of cross contamination is minimised. However, it’s worth noting that while vinyl food contact gloves comply with EC 1935/2004 and European Regulation 10/2011 they should not be used when handling fatty foods, as the oils can leach out the softening agents into the food and cause the glove to become brittle.

Medical grade vinyl gloves are also suitable for a variety of low risk applications even though they are not as durable as nitrile or latex and are ideal for housekeeping and hygiene.

What To Consider

Vinyl isn’t resistant against many chemicals, which is why it’s best for low risk jobs. However, vinyl gloves do not contain latex or accelerators that can cause type I and type IV allergies; so are ideal for those who suffer skin irritation caused by these agents.

Vi-ni gloves are a blend of vinyl and nitrile and give all the same properties of a vinyl gloves with the added benefit of a slightly higher tensile strength and a tighter fit compared to the standard vinyl.

For more information. our Complete Buyers Guide to Vinyl Gloves can help you.

Best for:

- food preparation tasks

- jobs that require high levels of sanitisation - such as cleaning tasks and when serving food

- when working with non-hazardous substances.

Why?

Polythene gloves are an excellent choice for disposable PPE. They are long lasting, durable and offer an effective barrier to minimise the risk of cross contamination. They are usually larger in size and are also available in arm gauntlet form to offer protection for forearms too. Smooth and embossed versions are available. Embossed polythene gloves offer a little more grip than their smooth counterparts.

Polythene gloves are best for maintaining good hygiene, making them a great glove to keep to hand in a variety of industries.

What To Consider

Polythene gloves are not the best choice when you require a higher level of touch sensitivity or when performing precise tasks that need a high level of detail. They can feel loose on hands due to their oversized design.

Polythene gloves should only be used for minimal risk jobs and are not suitable for medical purpose or contact with chemicals.

Now that you have a clear idea of what each glove type entails and which is best for you it’s time to select the right pair. Here’s how to get it right:

- Check your hand size before buying- Gloves that are too tight or too large will not offer the same level of protection as ones that fit correctly. Our comprehensive glove guide can help you work out the right size for you.

- Ensure gloves meet the protection standards you require- Most gloves are worn as PPE and therefore must comply with the regulations required to ensure tasks are carried out safely. Brosch Direct’s gloves all clearly list what they are compliant with to ensure you choose the right one for the task at hand.

- Check for a CE mark- This is an industry standard mark that ensures the gloves have undergone the correct testing and certification.